Linear Guideways: A Key Component in Industrial Automation

With the rapid development of industrial automation technology, precision mechanical components have become increasingly important in enhancing equipment performance and production efficiency. Among these automation components, linear guideways play a crucial role as one of the core elements. They are widely used in CNC machine tools, robots, automated production lines, and various industrial equipment, providing high precision and stable linear motion support.

1. Definition and Function of Linear Guideways

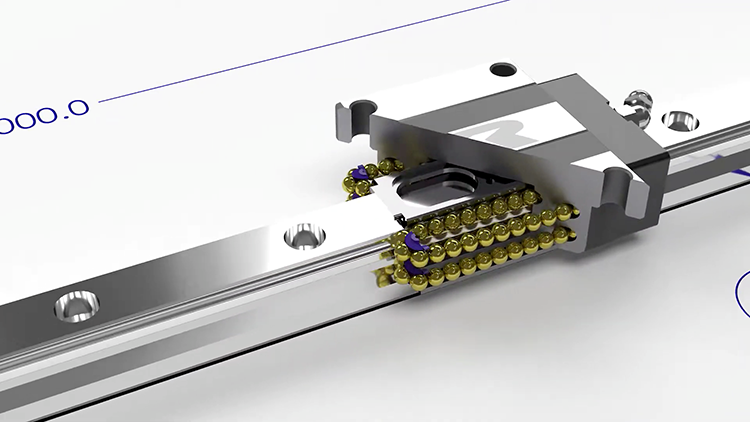

A linear guideway, also known as a linear slide or straight-line guide, is a mechanical component used to provide linear motion. It consists of a rail and a slider (or carriage) that moves smoothly along the rail with the help of rolling elements, such as ball bearings, ensuring high precision and stability during operation. Compared to traditional sliding guides, linear guideways have lower friction, smoother motion, and longer service life.

The primary function of linear guideways is to convert rotary motion into linear motion while maintaining high precision and stability, which is critical for many automation devices. They can support heavy loads while achieving high-speed and precise positioning, making them an essential part of CNC machines, precision machining equipment, and industrial robots.

2. Wide Applications of Linear Guideways

Linear guideways are used in nearly all industrial applications where high precision and stable motion are required. Below are some typical application areas:

(1) CNC Machine Tools

In CNC machine tools, linear guideways ensure precise movement of tools and workpieces along the X, Y, and Z axes. Since machining processes require extremely high precision, the stability and low friction of linear guideways directly affect machining quality and efficiency.

(2) Industrial Robots

Industrial robots are widely used in automated assembly, handling, welding, and other fields. Linear guideways play a key role in achieving linear motion in these applications, ensuring that robot arms maintain high precision and stability during complex operations.

(3) Automated Production Lines

In automated production lines, linear guideways enable precise positioning and high-speed material transport. For example, in linear modules and conveyor systems, linear guideways provide smooth motion with low friction and high load capacity, ensuring stable long-term operation of the equipment.

(4) 3D Printing

With the growth of 3D printing technology, linear guideways are becoming increasingly important in 3D printers. They ensure precise movement of the print head along the X, Y, and Z axes, improving the accuracy and efficiency of printing.

(5) Woodworking Machinery and Packaging Equipment

In woodworking machinery and packaging equipment, linear guideways provide precise linear motion to help complete tasks such as cutting, processing, and packaging. These machines often require high precision during long-term operation, making linear guideways an ideal solution to meet these demands.

3. Selecting the Right Linear Guideway

There are various types of linear guideways available in the market. Depending on load, precision, and speed requirements, choosing the appropriate linear guideway is crucial.

Linear Rolling Guideways: These are ideal for applications requiring high precision and low friction, such as CNC machines and industrial robots that deal with heavy loads and high speeds.

Sliding Guideways: Suitable for low-speed, low-load applications, typically used in lighter automation equipment.

Arc-shaped Guideways: Used in applications where curved paths are needed, such as certain special design automated systems or robots.

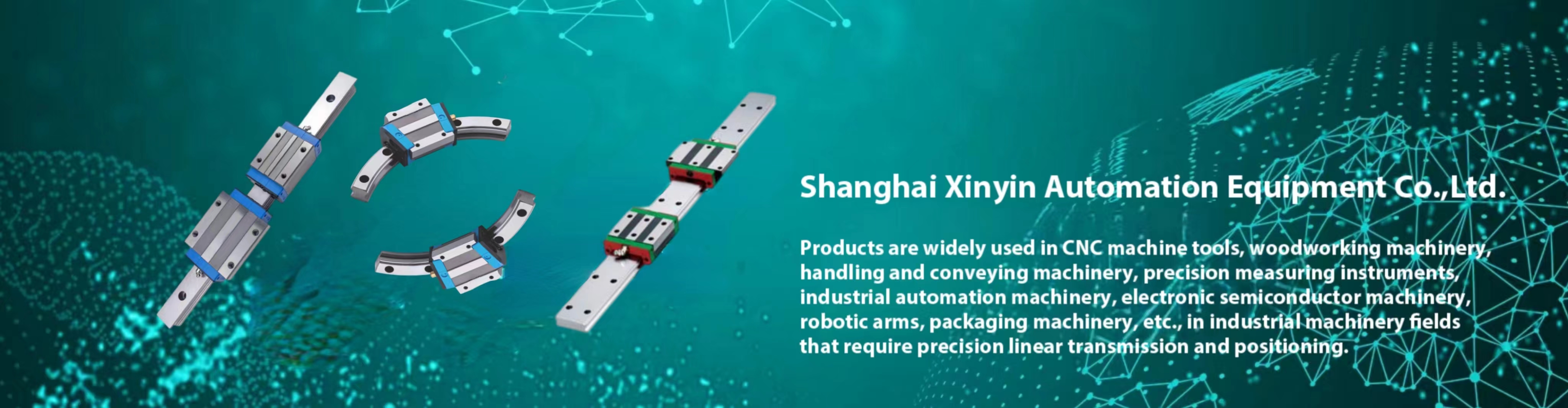

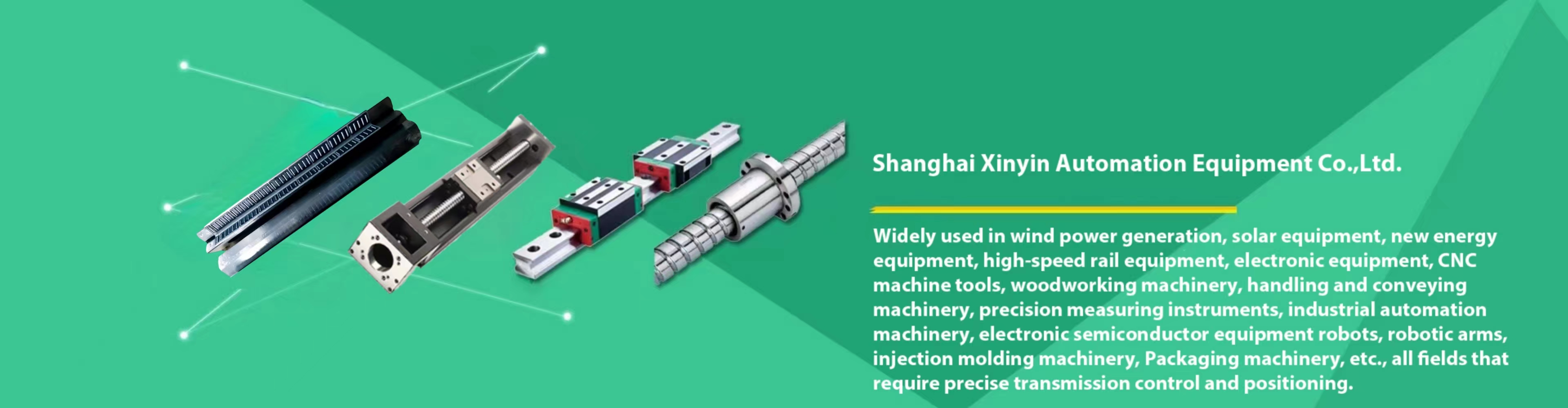

Shanghai Xinyin Automation Equipment Co., Ltd., as a linear guideway manufacturer, offers a wide range of high-performance linear guideway products that meet the demands of various industrial applications. Whether in precision CNC machines or high-speed automated production lines, Xinyin's linear guideways are recognized for their quality and stability, making them a preferred choice for many industries.

4. Maintenance and Care for Linear Guideways

To ensure that linear guideways maintain high precision and stability over the long term, regular maintenance and care are essential. Common maintenance practices include:

Cleaning the Rails and Sliders: Regularly clean the rails and sliders to prevent dust and oil contamination from affecting motion precision.

Lubrication: Periodically lubricate the guideway system with the appropriate oils or greases based on the operating environment, reducing friction and wear.

Wear Checks: Regularly inspect the rails for wear and tear. If any abnormal wear is found, timely replacement or repair is necessary.

Shanghai Xinyin Automation Equipment Co., Ltd. provides comprehensive after-sales services, helping companies with the installation, maintenance, and optimization of their guideway products to ensure that equipment operates at peak performance.

5. Future Trends

With the ongoing development of smart manufacturing and industrial automation, the technology behind linear guideways continues to evolve. In the future, linear guideways are expected to become more intelligent and automated. The introduction of new materials and technologies will further enhance their performance in extreme operating environments.

Shanghai Xinyin Automation Equipment Co., Ltd. continues to innovate and strive to provide customers with the latest and most advanced linear guideway products to meet the ever-changing market demands.

Conclusion

Linear guideways, as a critical component of industrial automation systems, are widely used in various fields requiring high precision and stable performance. Whether in CNC machine tools, industrial robots, or automated production lines, linear guideways play a vital role. When selecting the right linear guideway, it is essential to consider not only product quality and performance but also the operating environment to make the best choice.

As a professional manufacturer of linear guideways, Shanghai Xinyin Automation Equipment Co., Ltd., with years of industry experience, offers a range of high-precision linear guideways and automation components, including both HIWIN Group products and its own brand XYT. These products are widely used across multiple industries globally. By continuously improving technology and service, Xinyin helps customers optimize their production processes, enhance equipment performance, and promote the advancement of smart manufacturing.

- What are the advantages of ball screw linear modules

- Ball Screw Customization According to Drawing – The Key to Enhancing Precision Transmission Efficiency

- Custom Non-Standard Guide Rails: The Key to Enhancing Precision Motion and Positioning in Industrial Applications

- How to identify the authenticity of ball screws

- How much does one meter of linear guideway cost

- Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

- How to choose the type of ball

- Linear Guides in Automation: Applications and Future Trends

- How Much Does a Meter of Guide Rail Cost? Key Factors Influencing Guide Rail Prices

- Shanghai Xinyin Automation Equipment Co., Ltd. — Innovation-Driven, Precision Manufacturing