What are the advantages of ball screw linear modules

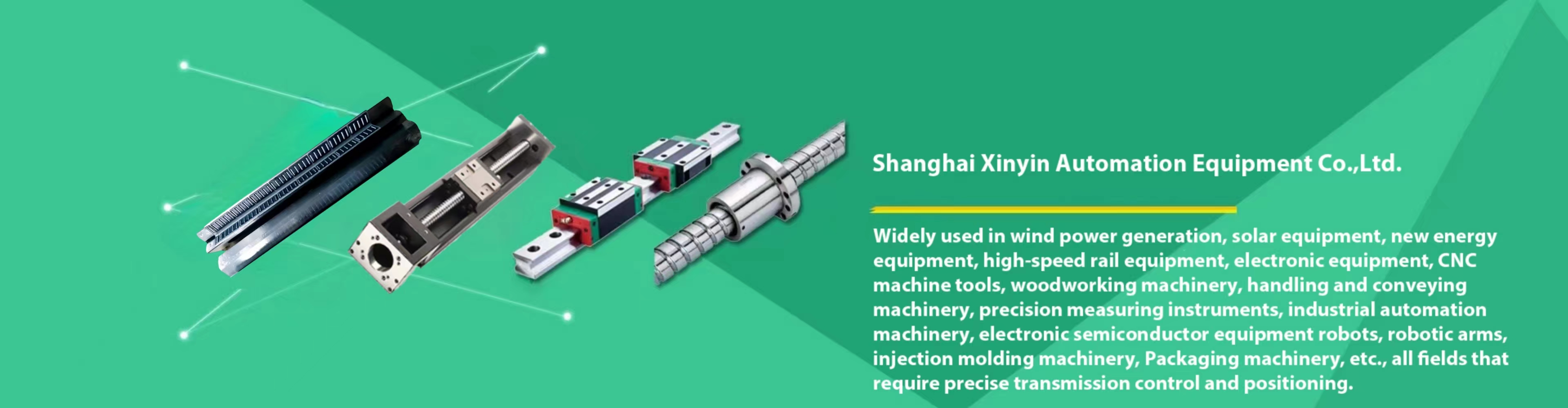

The most common ones on the market are synchronous belt linear modules and ball screw linear modules.

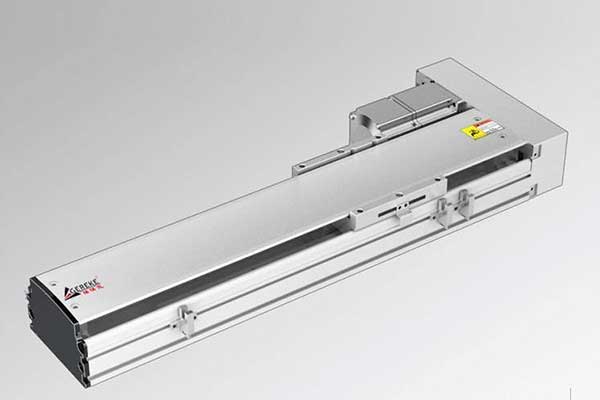

What are the advantages of linear modules of ball screws? The biggest difference between ball screws and synchronous belts is that the positioning accuracy of ball screws is relatively high, which is more suitable for use in high-precision mechanical equipment. If high-precision mechanical equipment It is impossible to use cheap synchronous belt linear modules. One is that the accuracy is not up to standard and the error is large, which will seriously affect the mechanical working ability. The linear module of the ball screw is characterized by relatively high stability, no vibration or deviation, which greatly improves the performance of mechanical products.

The synchronous belt type module has a larger stroke than the ball screw, but the synchronous belt type module can only be used on the X axis, while the ball screw type module can be used on the Z axis. And the load is also different. The load of synchronous belt type module is generally 10KG.

- How Much Does a Meter of Guide Rail Cost? Key Factors Influencing Guide Rail Prices

- Ring Rail Conveyor Systems: Pioneering Automation and Precision Transmission Technology

- Linear Guide Prices and Selection Guide: How to Choose the Right Guide for Your Needs

- What matters should be paid attention to when installing the ball screw?

- How to choose the type of ball

- Price of Steel-Inlaid Linear Guides and Their Applications in Industrial Machinery

- Ball Screw Customization According to Drawing – The Key to Enhancing Precision Transmission Efficiency

- Linear Guides in Automation: Applications and Future Trends

- Arc Rail Drive Methods and Application Guide

- How Much Does a Guide Rail Cost per Meter? Shanghai Xinyin Automation Equipment Co., Ltd. Explains